Innovating materials, transforming lives — welcome to the future of affordable, efficient heating.

Haydale – Creating Material Change

At our core, we are pioneers in nanomaterials, specialising in Plasma Functionalisation of graphene and advanced materials. But today, our mission is bigger — tackling fuel poverty with innovative, low-power heating solutions.

Our Just Heat range is designed to warm homes more efficiently, cost-effectively, and sustainably, helping us all move towards a greener, Net Zero future.

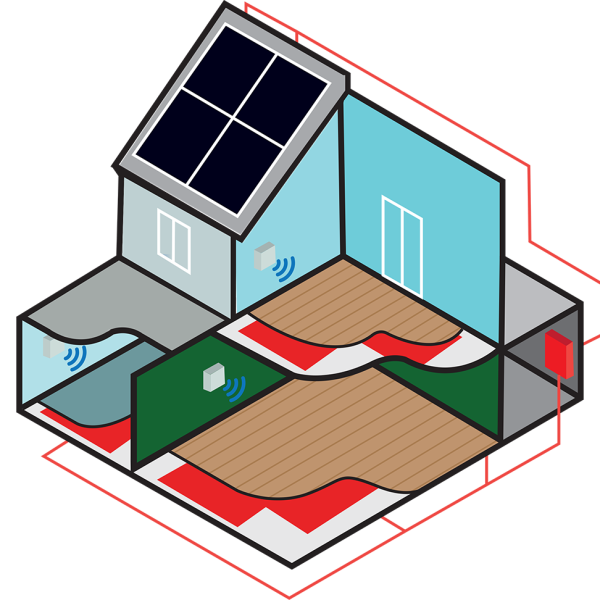

JustHeat: Functionalised Graphene underfloor heating technology – affordable and fast!

Haydale's innovative JustHeat underfloor heating system provides an innovative solution to key industry challenges. It helps combat fuel poverty by offering an energy-efficient and cost-effective heating option, making warmth more accessible to those in need.

The system is designed to simplify installation and maintenance, reducing common bottlenecks and ensuring a smoother process for homeowners and installers alike. Additionally, its energy-efficient design supports net zero goals, contributing to a more sustainable and greener future.

Unlocking Graphene

Graphene can radically improve the properties of the materials products are made from. Discovered in 2004, the use of graphene has been slow due to its inert nature. Making it mix with other materials is difficult and chemically complex.

Haydale has developed a powder in, powder out process that overcomes this problem called plasma functionalisation.

Unlike other methods that use complex and damaging chemical processes, the Haydale HDPlas® method is a dry, clean, and environmentally friendly process that unlocks the properties of graphene and other nanomaterials to give products improved mechanical strength and increased electrical and thermal conductivity.

Unlock the potential of graphene with the help of Haydale – making your products leap ahead of competitors.

Advanced Material Products

Functionalised Graphene

There are a wide range of opportunities for functionalised graphene and our technology unlocks the real potential of this ‘wonder’ material.

To make them work, graphene and other nanomaterials need to be treated. This changes the surface chemistry of the material releasing all the delights these materials have to offer. However, for quality, high-volume production, the method used is important.

Haydale’s HDPlas® technology holds the key to unlocking the world of advanced materials for your products.

Graphene Inks

Haydale has a range of customisable graphene inks for use in biomedical devices, flexible electronics, heating elements and wearable technology.

Produced in the UK, our inks are manufactured using the HDPlas® functionalisation process – an environmentally friendly, sustainable plasma process that functionalises an array of graphene-enhanced materials.

Elastomers and Rubber Technology

Haydale has developed a range of functionalised graphene and nanomaterial additives for use in elastomer product manufacturing.

Through functionalised nanomaterials we have improved strength, weight, abrasion and wear, leading to better product performance and increased lifespan.

Applications include rubber bicycle and road tyres, footwear rubber soles, seals, and gaskets.

Functionalised Boron Nitride

Boron nitride, sometimes referred to as ‘white graphene’ is an ideal material for a wide range of applications. The synthetic ceramic material is non-toxic and available in solid and powder forms. Untreated it presents the same problems as graphene so to unlock the great properties of insulation, strength, weight and electrical conductivity it needs to be functionalised.